- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Place of Origin: beijing

- Brand Name: demina

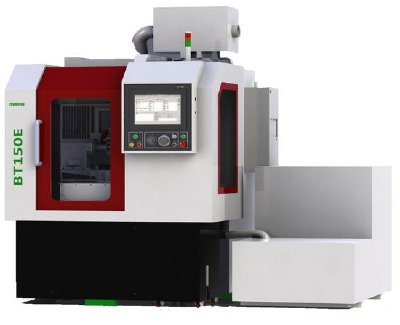

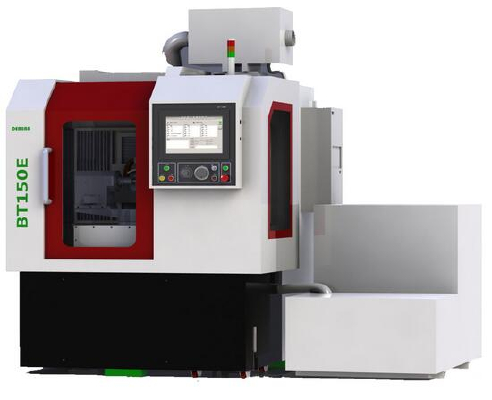

- Model Number: BT-150E

CNC tool grinder, grinding wheel is composed of a horizontal axis (X axis), wheel vertical axis (X axis), workpiece axis (Y axis), the horizontal axis (C axis) and the axial rotation axis (A axis) five axis CNC. The machine is suitable for mass production and grinding of rotary cutter, milling cutter, such as drill points (including shovel behind angle and double plane angle), the end of the cutting gun drill, especially suitable for manufacturing and all kinds of super hard alloy cutter rotary cutter grinding.

First, the characteristics of machine tools:

1, mechanical structure of the machine: machine tool bed (base) using integral castings weighing 1.5 tons, can meet any requirement of superhard material grinding. The machine tool has a grinding fluid shield to ensure that the grinding fluid is not splashing around. The machine is equipped with lights inside the bedside lamp and machine tool.

2: the machine tool spindle grinding head with high precision variable speed spindle power: 5 kilowatts, the maximum speed up to 6000 rpm, the use of recycled water cooling, the rotating precision grinding spindle end jump 0.002 mm, 0.003 mm diameter jump.

3, the machine linear navigation: the needle NO rail with high precision, the rigidity of machine tool, precision and durability are obviously improved.

4, servo mechanism: the servo control structure, three linear axis (X axis, Y axis, Z axis) and two axis (C axis, A axis) is controlled by a servo motor, which can make five axis drive in an application program. The grinding efficiency is improved, and the quality of the cutting edge is improved.

5, control system: Germany times Fu (BACKHOFF) company's five axis linkage digital control system (TWINCAT), the system resolution is 0.0001 mm. System for the WINDOW operating system, to provide an open development interface, the user can be transported to the special preparation of non-standard tool grinding program.

6, lubrication system: lubrication system using intermittent automatic grease lubrication system, the user can set the time of filling and filling time interval, to ensure the service life of the screw rod.

Two, BT-150E diamond tool grinding tool grinding application software package

Option one, using the grinding software independently developed by our company, you can set the angle of the cutting tool, the arc size and feed speed of grinding parameters on the tool center after the end of time through the software to set basic parameters, machine can be automatic grinding high precision tool. All the parameters of the machine tool is managed by the database system, which is convenient to store and search through the processing procedure.

1, software package 1: bit software package, the software package is used for the typical shovel behind the angle of the drill and the double plane back angle of the drill bit, can not open the groove and the edge of the drill.

2, software package 2: milling tool software package, the software package for the following four edge of the vertical milling cutter grinding (including the ball head knife and R knife). Grinding sequence can be arbitrarily arranged, the process data can be edited, these parameters can be continuously optimized, and then stored in the database for the use of.

3, the package 3, gundrill software package, the package can end grinding gun drill, including five small plane and chamfer.

4, according to the user design requirements and process requirements of the development of the blade grinding software package.

Option two, the Swiss TOOLBOX tool grinding software package, based on the five axis CNC tool grinder EDP system, perfect function, easy to operate, for the production of high precision tools and grinding tools provided a powerful tool box.

1, the characteristics of the application

The graphical interface software is suitable for any type of CNC tool grinding machine (at least five axes), the various stages of development of the equipment can be used. The operator will not be skilled as long as a few days of training. Each NC axis can be configured with the left, the direction, the limit, the workpiece clamping position, spindle installation position, probe and tool blank, for the overall layout of the machine tool provides unlimited possibilities.

2, the structure of the software package

The tool kit has a tree structure, wherein the function node can be opened or closed according to the needs of users. In the online help instructions, the user can quickly set up the tool data in the operation process. The tree structure of the operation, we provide the following information: the specific operation option, geometric parameters, the structure of machine tools, grinding parameters, grinding cycle definition, parameter modification, specific process parameters, process the input and output skills. For example, the processing of the tool groove, the software not only provides a basic algorithm based on the groove, but also provides a comprehensive grinding wheel shape. The various elements in the tool structure are set up according to the tool options. And the type of tool structure matched is: each tool has a structure formed by several operations: if both the simulation can also be in actual grinding machine.

3, grinding wheel

This kit is also optional optional standard wheel molding wheel, strong type grinding wheel, grinding wheel (or wheel group) size by three-dimensional geometry definition: can choose the wheel for a particular process, and set specific processing conditions, these are completed in the graphics prompt.

4, the introduction of grinding wheel / grinding wheel group

The following is the standard features of the software: set the size of the grinding wheel, the type and function of the grinding wheel, the axial position of the grinding wheel, the rotation direction, the composition of the material and the grinding wheel group, etc..

5, the definition of grinding wheel shape

The following is the standard function of the software: the geometric parameters of the grinding wheel, the automatic drawing of the shape of the grinding wheel, the shape of the grinding wheel automatically according to the groove shape of the cutter.

6, the definition of tool

The software can define a variety of shapes of the cutting tool, the head includes: milling cutter, drill bit, deep hole drill, ball head,

- Place of Origin: beijing

- Brand Name: demina

- Model Number: BT-150E